Filacorp

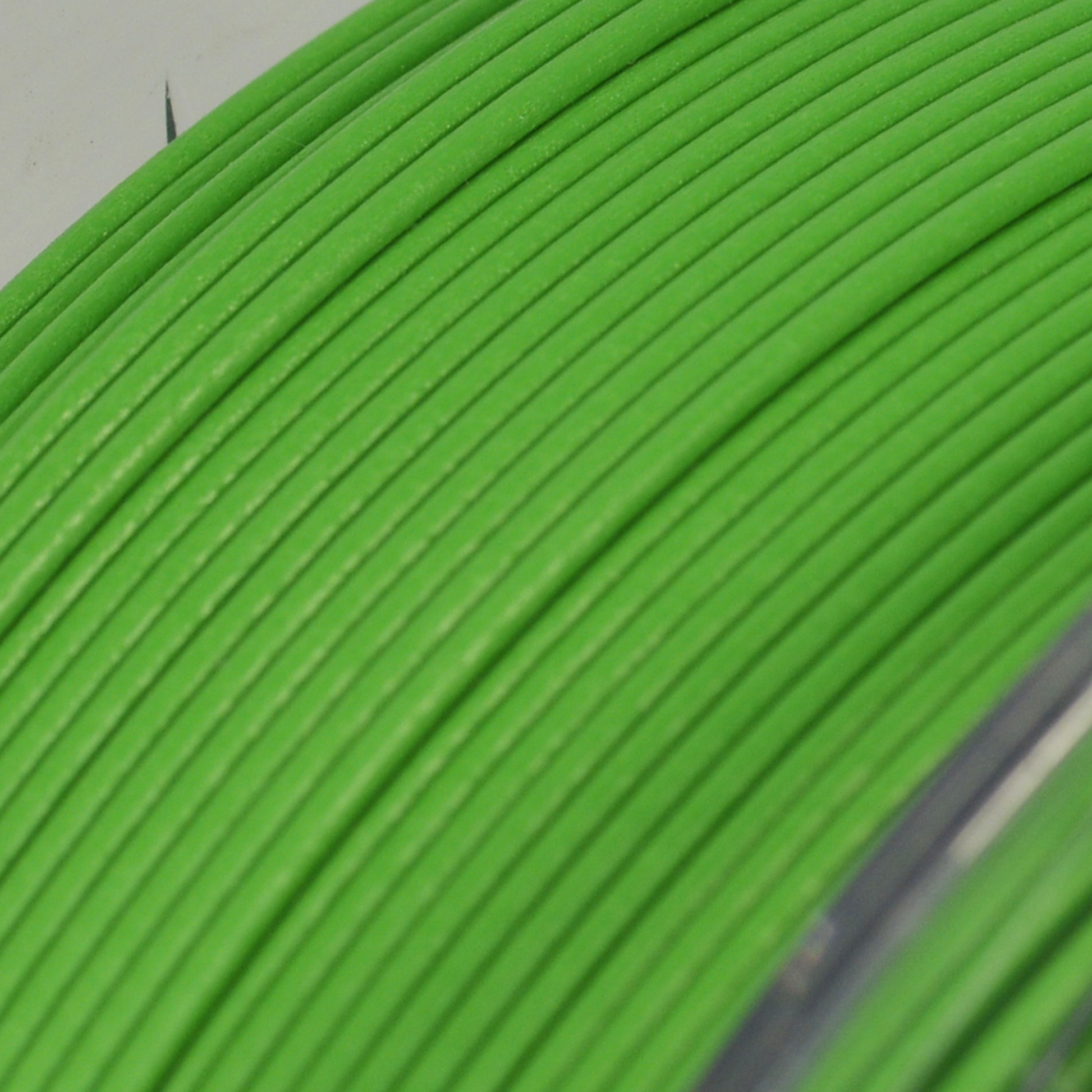

rPLA Satin - Emerald Green

rPLA Satin - Emerald Green

€0.86 Spool Deposit Included — refunded on return

Buy 5 for €11.99 each (€0.86 spool deposit included)

Couldn't load pickup availability

About rPLA Satin

Filacorp rPLA Satin features a precise manufacturing tolerance of ±0.03mm, top speed of 1000mm/s and is made out of 100% recycled PLA. This high-quality filament offers a sleek, shiny finish, perfect for creating stunning and sustainable 3D prints.With sustainably sources pigments, the colour additives come from renewable resourced materials.

Compared to standard PLA, our rPLA Satin provides the same high-quality performance, with no compromises on strength or durability. It excels in delivering outstanding 3D printing results that have both a superior finish and eco-friendly background, making it an ideal choice for sustainable creations.

Recommended Print Settings

-

Nozzle Temperature

225 (± 10 °C)

-

Print Bed Temperature

60 (± 5 °C)

-

Fan Speed

100%

Key Attributes

-

Pros

Easily Printable

High Speed Printing

Environmentally Friendly

Negligible Warping & Shrinkage

Suitable For Various Print Sizes

-

Cons

Limited Print Flexibility

Low Temperature Resistance

Absorbs Moisture (Hygroscopic)

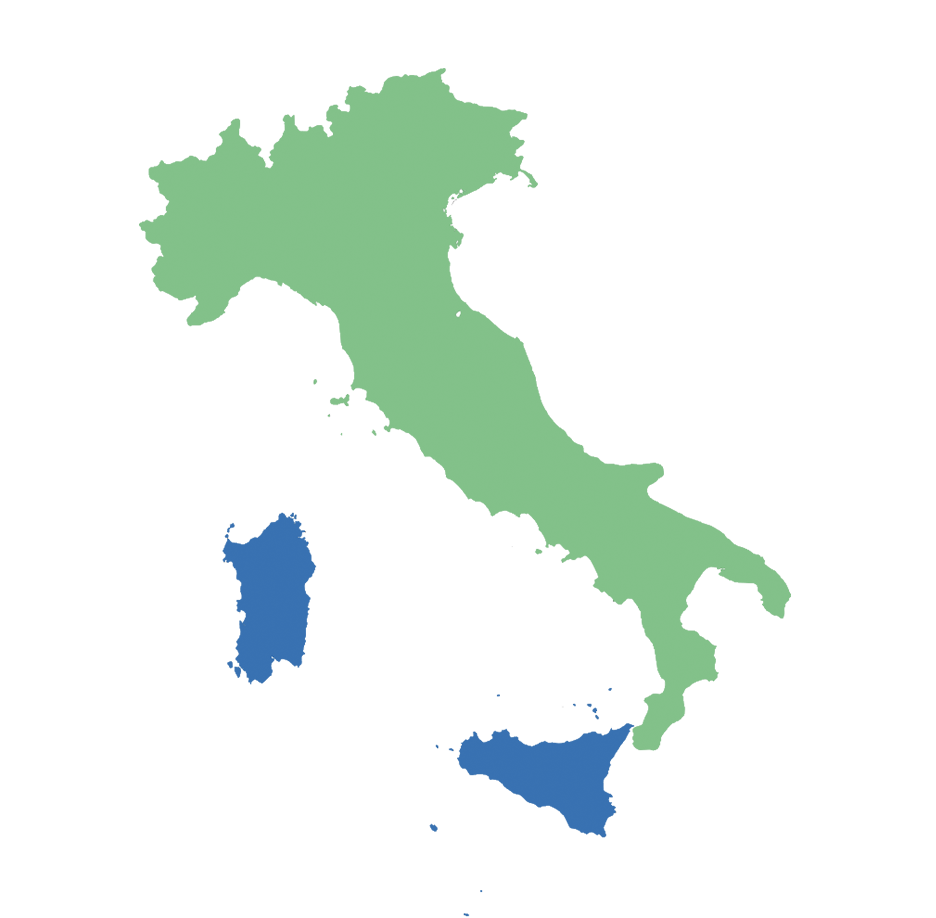

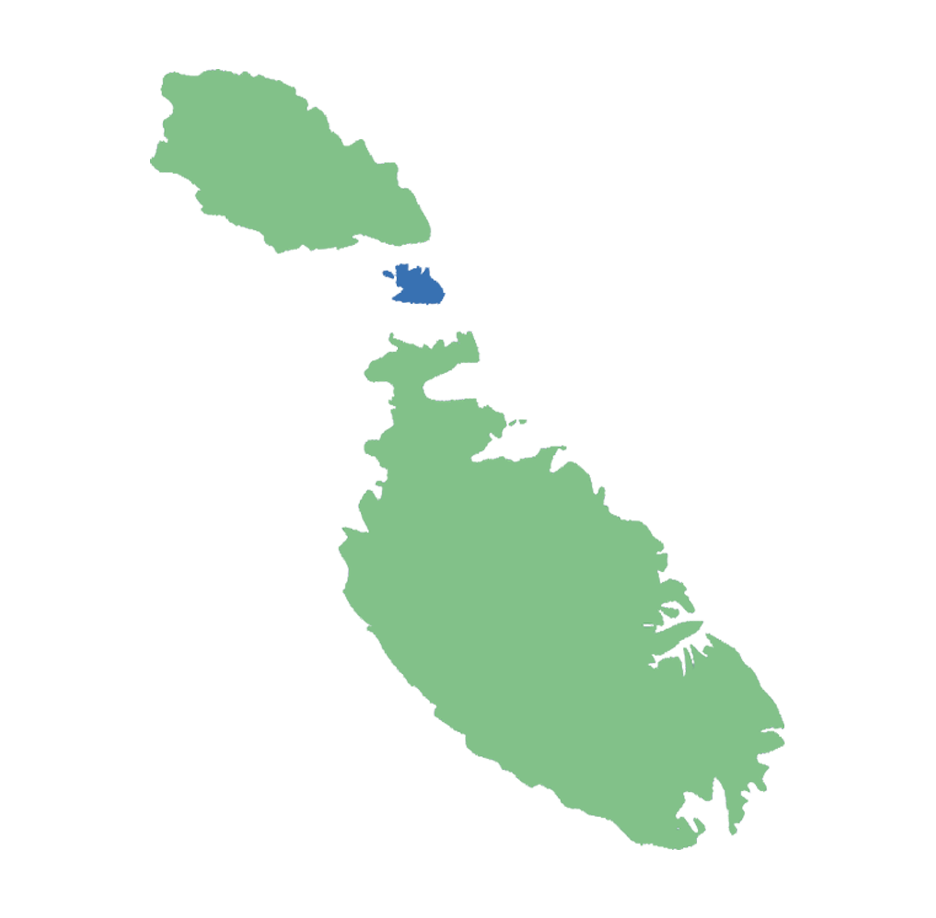

sourced from italy

Our rPLA Satin Pellets

The foundation of our rPLA Satin Collection lies in premium recycled PLA pellets sourced from Italy. Known for their exceptional quality, these pellets are the starting point for a filament that blends elegance with eco-conscious performance, ensuring a flawless printing experience every time.

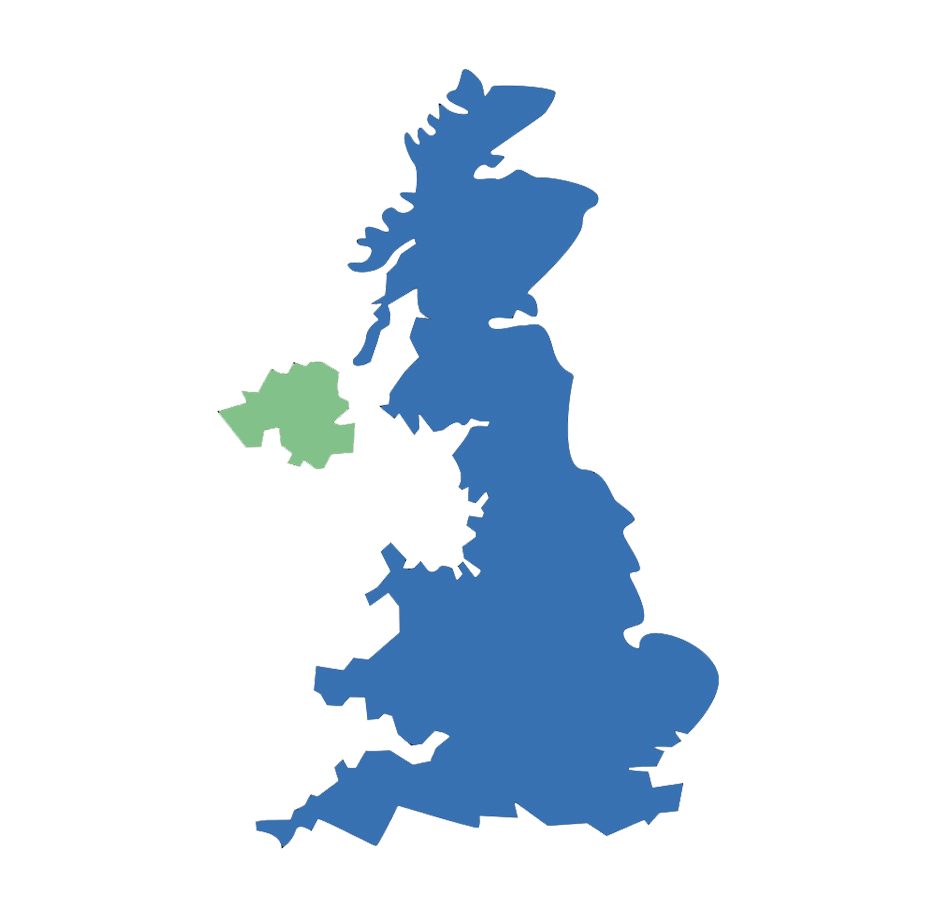

sourced from United Kingdom

Our Colour Range

The rPLA Satin Collection boasts refined, luxurious colours, crafted using pigments sourced from the UK. Produced with sustainability in mind, these eco-friendly hues are carefully selected to enhance the smooth, premium finish, adding a touch of sophistication to every print.

proudly manufactured in Malta

Where it's Made

Every spool of our rPLA Satin Collection is proudly manufactured in Malta, where innovation meets artistry. With a commitment to precision and quality, we transform recycled materials into filament that redefines sustainable 3D printing. Each spool is a testament to Malta’s growing legacy in sustainable manufacturing and our unwavering dedication to excellence.

Customers also bought

-

Sold Out

Sold OutrPLA Prime - Transparent

Regular price €11,85 EURRegular priceUnit price / per€14,65 EURSale price €11,85 EURSold Out -

Sold Out

Sold OutrPLA Prime - Frost White

Regular price €11,85 EURRegular priceUnit price / per€14,65 EURSale price €11,85 EURSold Out -

rPLA Prime - Midnight Black

Regular price €11,85 EURRegular priceUnit price / per€14,65 EURSale price €11,85 EURSale -

rPLA Prime - Shark Grey

Regular price €11,85 EURRegular priceUnit price / per€14,65 EURSale price €11,85 EURSale