Eco-Friendly Innovation: Utilising Recycled PLA for 3D Printing Filament

The importance of sustainability is growing in the rapidly changing field of 3D printing. The utilisation of recycled PLA (polylactic acid) to make 3D printing filament is one creative option that is gaining popularity. This ecologically friendly method not only minimises waste but also creates new opportunities for manufacturers and producers that care about the environment.

What is Recycled PLA Filament?

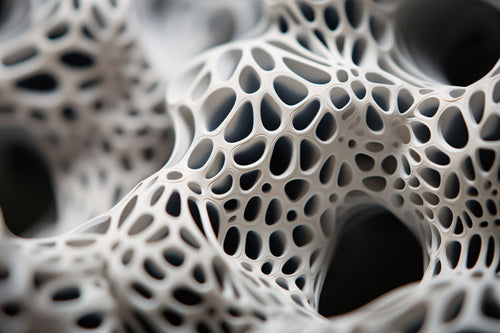

Recycled PLA filament is a sustainable 3D printing material made from repurposed PLA-based products, including packaging, food containers, disposable cutlery, and many more items. Polylactic acid, sometimes known as PLA, is a thermoplastic that can be composted and biodegraded. It is made from renewable materials like sugarcane or cornflour.

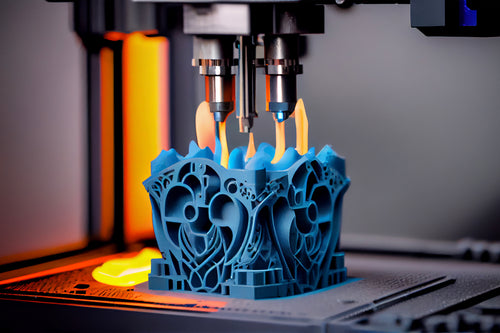

The first step in making recycled PLA filament is gathering PLA trash from different sources. Items that have reached the end of their useful lives, leftovers, and extra material produced during the production process are all included in this garbage. After it is gathered, the PLA waste is cleaned and sorted to get rid of impurities and get it ready for processing.

To improve its qualities even further, the recycled PLA filament may go through extra processing procedures including stretching, annealing, or chilling after extrusion. The filament is then bundled and spooled, making it suitable for use in 3D printing applications.

Many of the advantageous characteristics of virgin PLA, such as biodegradability, low toxicity, and ease of printing, are still present in the resultant recycled PLA filament. But it also has the added advantage of keeping garbage out of landfills and lowering the need to produce new plastics.

Benefits of using rPLA

-

Environmental Impact

This filament minimises the carbon impact associated with typical filament production and lessens dependency on new resources by recycling PLA waste.

-

Cost-Effectiveness

Recycled PLA filament is frequently less expensive than virgin PLA, which is great for those who are on a tight budget.

-

Versatility

Recycled PLA is just as versatile as regular PLA filament, with a wide range of uses spanning from prototypes to functional components and creative creations.

Applications of rPLA Filament

Recycled PLA filament, made from recycled PLA-based products including food containers and discarded cutlery, offers a sustainable 3D printing alternative. Recycled PLA components are carefully gathered, cleaned, and extruded to create filament with a uniform diameter and quality that may be used in a variety of applications.

In addition to lowering waste, this environmentally friendly filament keeps the advantageous qualities of virgin PLA, such as biodegradability and printing simplicity. Prototyping is another area of its adaptability that allows engineers and designers to efficiently iterate concepts while minimising material waste. It is a perfect resource for educational initiatives that promote 3D printing literacy and environmental consciousness in communities and schools.

Recycled PLA filament may also be used by designers and artists to add a distinctive eco-friendly touch to their works, helping to create a more sustainable future for both fashion and the arts.

In Conclusion

Recycled PLA filament is a potential development in the field of environmentally friendly 3D printing materials. Utilising the potential of recycled materials, producers and manufacturers may minimise waste, and help the industry move towards a green printed future.

Recommended for you